People are invisible until you're inside the plant. Outside, from across the street, the concrete factory is just metal bulk, massive machines, thick iron chains, and gigantic ducts that rise from the banks of the Duwamish River. You walk on the lot in much the way an ant enters an industrial kitchen. Everything feels too big, and you feel too vulnerable. At any moment, your soft body could be crushed by something hard and heavy. CalPortland, however, is a pretty safe place. A sign on its office building announces that 175 days have passed without a "lost time accident."

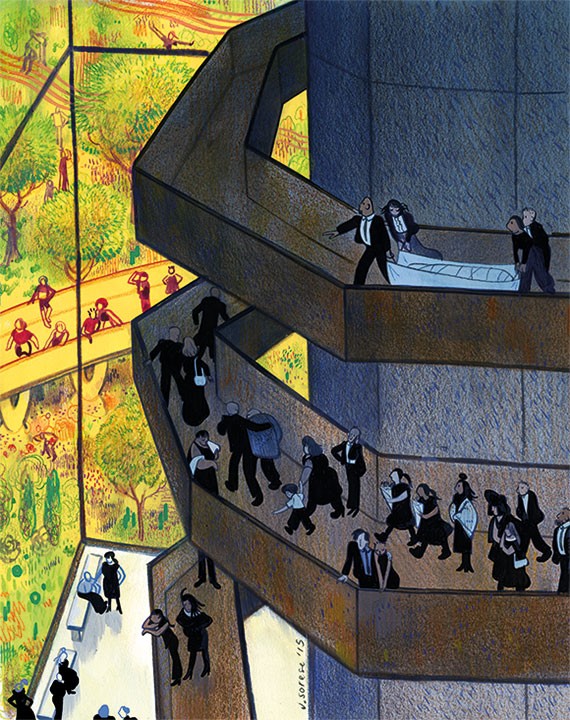

A barge brings the plant gravel from a pit in DuPont. The gravel comes in three sizes—tiny, less tiny, and not tiny. Cement, sand, water, and gravel are the basic materials for concrete, the ur-stuff of the city. Towering cans at the back of the plant store these materials. Conveyor belts run up to and down from these cans. Water is pumped through a network of pipes. There's lots of activity on the ground (small humans handling massive machines) and lots of trucks entering and leaving the plant. Each truck has a white and perpetually rotating egglike drum. If a truck's egg is empty, the driver parks under the mother of all the eggs (the massive and muddy center of the factory, the point at which production meets distribution) and receives fresh concrete.

A walkway connects the massive drum with the main office building. From the entrance to the office building, you can see the corporate and civic towers of downtown. At the top of the office building is a dispatch center operated by men and women who track the movements of trucks around the concrete-hungry city and the plant area like air traffic controllers manage and monitor arriving and departing planes. The main egg's gravid and metal turning shakes the whole dispatch center. Desks, computer screens, coffee cups, pictures of spouses, children, and loved animals shake with this shaking that no one seems to notice. Only I recognize it. They are long used to it. This is how it feels to make things in Seattle.

"Concrete has come so far," says Dave Siemering, the production manager. "You get down into an old part of town like Pioneer Square and you see these buildings that were made in the early 1900s. They are still standing, they are still strong, they are still beautiful. But we have the ability to make concrete stronger than the concrete in Pioneer Square. Our concrete is super, super strong." Siemering sits at his desk. His office is spacious and being remodeled. Men remodeling his and other offices are listening to Stevie Nicks sing: "Like a heartbeat drives you mad/In the stillness of remembering/What you had/And what you lost..." Directly above us is the shaking dispatch center. Outside is the end of "cement alley" and the beginning of Boeing Field (though Boeing does its heavy-duty manufacturing elsewhere). Plane after plane descends from the sky as humans in hard hats hold python-sized pipes and hose down machines processing this or that stage of a thick substance that will eventually harden into a bridge, tunnel, or building.

"The concrete we make is not only super-strong, it's super-pliable," Siemering adds. "Rain falls, and the concrete is porous, so it drains right through it and you don't have standing water or problems with ice."

Siemering stands. He is tall. He walks with purpose to the other side of the office, picks up a small block of concrete, and hands it to me. Concrete is so real, so there. I hold and revere the hard thing made by the men and women of CalPortland. This particular plant—part of a network of similar plants owned by a global cement corporation based in Japan called Taiheiyo Cement—employs about 110 people, a small fraction of the 30,000 people who wake up in Seattle, go to work, and make stuff. Yes, lots of people in Seattle work in factories and not just in offices or coffee shops. In fact, the number of factory workers is not declining but growing. Last week, the Seattle Times ran a front-page story about how the state's manufacturing sector is adding jobs to the economy (14,000 over 12 months). And most of this growth is happening here in Seattle and outpacing other sectors.

The people in a factory at the end of Ballard Avenue Northwest are putting the finishing touches on a bright orange awning. The factory, Canvas Supply Company, also makes accessories for boats ("sails; window, floor & wall treatments; cushions; upholstery; furniture; decorating; bedding/soft goods; and of course, ANYTHING MADE OF CANVAS"). Whereas the Duwamish Manufacturing Industrial Center is really about building and reinforcing the city (cement, concrete, the production of steel), the Ballard Interbay Northend Manufacturing & Industrial Center is really about building and reinforcing sea vessels (making, fitting, supplying yachts, cruisers, boats). This is our marine-industrial complex.

Canvas Supply Company has been around since the end of the 19th century and has a family atmosphere. Indeed, my guide through the factory, Sarah McLauchlan, is the daughter of the vice president, Bryan McLauchlan. The vice president is brother to the president, Tony McLauchlan. "Our company supports 28 families," Sarah McLauchlan says with deserved pride as we walk into Canvas Supply's designing room. The small room has a view of the end of Ballard Avenue, a street that was once lined with light industry and warehouses but is now lined with upscale and middle-scale bars, restaurants, and cafes. That part of Ballard is definitely postindustrial; this part is not.

The main floor of the factory has machines with big spools of thread and huge rolls of materials. It is not a noisy operation and it has the kind of warmth and honesty that only an old wooden building can provide. You feel at home here. The men (I did not see women in the main section) go about making things with great ease and care. They are so focused on the job that they fail to notice me, a tourist from culture land visiting factory land.

After showing me the basement area (they make combine drapes for harvesting pea pods), McLauchlan leads me outside, to the left, and into a section where Canvas's mattresses are made. This section of the factory has a master. His name is Bob Karge. He is a jolly good fellow. "I have not been unemployed since 1973," he says and laughs heartily. "Yes, made my first mattress back then and have never stopped." Indeed, this is his kingdom, his place, his meaning on earth—this small but busy shop that makes the furniture for human sleep. And how can you not admire Bob? The men or women who conquer the whole world do not impress us as much as those who have turned some small corner of the world into a world of their own.

"We make mattresses for boats and for homes," he says. "But we began, of course, by making mattresses for boats. We later expanded to homes." What's their best-selling mattress? Bob looks me up and down and then points to a set of mattresses against a wall: "Those are. They're green mattresses. No petroleum was used to make them. They're made from natural rubber. They have no springs and meet fire standards. Everybody is crazy about being green these days."

Bob speaks the truth. Steve Young, the manager of Seattle Mattresses, Canvas Supply Company's store on 15th Avenue Northwest, confirmed that the green mattresses are the company's hottest items. They are advertised as "Made in Ballard."

As Ballard makes mattresses, on the other side of town, in the quiet part of Capitol Hill (19th and Prospect), the people at Luna Sandals are drilling holes in the soles of minimalist running shoes. This factory is not your typical factory. It's above a beauty salon and is surrounded by big trees, expensive houses, and private schools. It has four or so heavy machines (standard drill presses), shelves containing materials (fabric, straps, leather, vegan leather, rubber, buckles), a main desk (at which the founder, Barefoot Ted, sits and receives orders or makes deals), and a central table where the sandals are assembled.

During my visit, nine casually dressed women and men are at work at this table. On an internet radio station, Paul Banks revives Ian Curtis's ghost: "Surprise, sometimes, will come around/Surprise, sometimes, will come around/I will surprise you sometime/I'll come around when you're down." Sunlight fills the small space. One of the employees, Dylan Romero, guides me through the process of making a Luna sandal. (On the company's website, Romero is pictured eating the leg of an animal that looks wild, recently killed, barely cooked. This image prepared me to meet the wrong person; instead of a lusty, loud, loquacious type, I met a very mellow and affable human being.)

We begin with the shelves by the factory's entry, then proceed to the drills along the walls, then come upon a tree stump that's used for hammering and banging things. The Luna sandal, he explains to me, is a part of the minimalist movement. What this movement wants more than anything else is to reduce the running shoe to the brink of nothingness. Purists, of course, want nothing but nothing. Barefoot Ted, a runner who is featured in the popular book Born to Run and heads a school of sorts for those who want to master the art of running with what god gave you, is not in this camp. Though committed to barefoot running, he believes there are exceptions: There are places (rocky hills or city streets) that require something to protect the human foot from the world. He discovered that something in Northern Mexico, where a rugged people (Tarahumara Indians) make the sandals out of old tires. These most rude/rudimentary of shoes are used for work and sport.

Barefoot Ted returned to Seattle with the idea of these sandals impressed on his mind. A little thought and a few experiments led him to replace the old tire with materials from Vibram, the makers of FiveFingers barefoot shoes. A company was eventually born and named after the Mexican runner Manuel Luna. All of this happened in 2006. Six years later, Barefoot Ted's small-scale operation exports a variety of these sandals to any part of the world that the global mailing system can access.

"We are doing very well and growing," explains Romero. He is a big fan of the sandals because they conform to his feet and don't stress his joints the way regular running sneakers do. "But yesterday morning, Don Imus mentioned us on his radio show, so we are very busy today. We usually have three people working at a time, but today we had to call in friends to help us meet these orders. It's pretty weird that a small hippie company got great publicity from Imus." One of the factory workers, a tallish young man assembling sandals at the table, takes a break and hugs the woman working next to him. She hugs him back. They have a moment. CalPortland is about massive machines; Canvas Supplies, families; Luna Sandals, friends.

Tsue Chong Co. Inc. makes 65 million fortune cookies a year. These cookies are almost everywhere you're served Chinese food in the Northwest. The factory is at the border between Little Saigon and Chinatown proper. Because the managers of the factory will not grant me a visit over the phone, I show up in person and beg them to let me in. I am told, again and again, that they only let students from Seattle's school district into the factory, not people from the media. This rule makes no sense. I try to change their minds by showing how unreasonable they are. No argument moves them.

Not far to the west of the Tsue Chong fortune cookie factory is the headquarters for Vulcan, Paul Allen's investment company. That company is transforming South Lake Union into a center for code and culture production. South Lake Union wants to be the very opposite of the industrial areas near the Duwamish and in Ballard—South Lake Union wants to be postindustrial, post- Fordist, postmodern.

I never get inside Seattle's fortune cookie factory. But something does happen. Just as I am about to leave, the door for the loading dock lifts and presents an amazing vision: Asian men moving around in a dreamy world of white, floating flour particles. (Women also work here, but none are evident at the moment.) There is the heavy machinery, the heat, the baking, the hairnets, the surgical masks, the hum, the final cookies with their messages. It is as if by some trick of magic, a factory in Shanghai had become visible. The more I stand there, the more my enchantment deepens. After a few minutes pass, the door drops and conceals the world of making things. ![]()